Structural, maintenance, repair and rehabilitation experts

November 30, 2022

Cutting-edge Electrical Engineering Services

January 11, 2023Quality dam inspections, maintenance and rehabilitation:

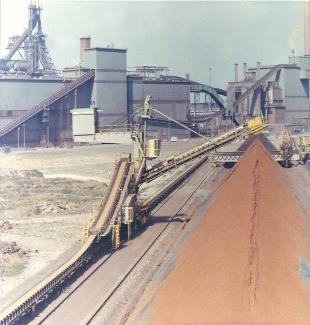

LNW Consulting Engineers and Project Managers remains the first point of contact for quality dam inspections, maintenance and rehabilitation programmes. Our expertise spans earth wall, attenuation, tailings, dirty stormwater and process water dams. This is in addition to water reservoirs, cooling towers, water pipelines and pump stations.

Cutting-edge dam inspection, maintenance and rehabilitation

Our engineers and technologists are at the cutting edge of dam inspection, maintenance and rehabilitation practices. Dam inspections are undertaken as part of our long-term maintenance repair programmes or to certify the structural integrity of this infrastructure so as to ensure compliance with statutory requirements. This includes Section 123(1) of the National Water Act of 1998 [NWA.PDF (dws.gov.za)]; the Occupational Health and Safety Act [Occupational Health and Safety Act 85 of 1993 (www.gov.za)]; and the Mine Health and Safety Act [Mine Health and Safety Act 29 of 1996 | South African Government (www.gov.za)]. These services are complemented by our dam operational and maintenance plans. They are helping to ensure the safe operation of dams according to their original design and intended purpose. We have also recertified dam designs or redeveloped old inundated operational and maintenance plans in line with changes and amendments to safety regulations and legislation. This service is provided as an extension of our focus on the upkeep of existing dam infrastructure. While our main focus is on mine embankment earth wall dams, we are also skilled and experienced in other industrial dam-type infrastructure with mechanical and electrical equipment. We are, therefore, strategically positioned as a single point of contact for dam routine inspection and strategic repair programmes. Furthermore, we specialise in “remaining asset life cycle” studies. This entails measuring fatigue against equipment operational cycles and comparing redundancy to efficiency.

Dam inspection, maintenance and rehabilitation solutions

We demonstrate our leadership in the field by the many innovative dam inspection, maintenance and rehabilitation solutions and methods that we have developed. Safety and structural assessments of infrastructure are undertaken with drones that have been equipped with the latest state-of-the-art photographic and thermographic imagery equipment. Bathymetric surveys of dammed water bodies are undertaken with underwater remote-operated vehicles that have been fitted with sonar devices and scanners. This enables us to undertake a comprehensive inspection and analysis of the structural integrity of dams throughout their design parameters and failure modes. These techniques have successfully addressed the many limitations of physical inspections. Constraints, such as high costs, as well as poor access to this infrastructure due to thick vegetation and dangerous wildlife, have prevented the detection of early failure development. Aerial infrared and photographic surveys can be ortho-rectified and combined with geographic information systems. This improves the effectiveness of continuous predictive/preventative maintenance programmes of earthen dams and levees. Aerial surveys can also accurately identify leaks and breeches in dams, levees and catch ponds before failures occur. Our technicians on the ground use the geospatial information generated from these surveys to locate, document and sample specific locations where there may be leaks or seeps. “Trending” this information pinpoints and alerts owners of possible dam failure points. Infrared survey technology optimises temperature; specific environmental conditions; vegetative cover; and water levels. In this way, the technology maximises the results needed to properly survey entire dam systems. Moreover, it can differentiate between wet areas and groundwater flow. This is in addition to detecting flows under water in lakes, rivers and waterways. Using infrared technologies, protecting waterways near dams; levees; and catch and run-off ponds can be undertaken more effectively. Moreover, we have developed our own analytical models and evaluation protocols to evaluate and compare dam inspection fieldwork and survey results against original dam design and maintenance plans. These inform our quality dam maintenance and repairs.

Cutting-edge dam inspection, maintenance and rehabilitation

Learn more about our cutting-edge dam inspection, maintenance and rehabilitation services that are prolonging the lifecycle of infrastructure assets by visiting https://lnw.co.za/. Established in 2001, LNW Consulting Engineers and Project Managers (Pty) Ltd consists of a team of skilled and experienced civil, structural, mechanical and electrical engineers, as well as technologists. We deploy these extensive skills, experience and capabilities to upgrade and renew plants; as well as for undertaking asset re-engineering; continuous improvements; maintenance; and materials-handling projects. Moreover, we provide complete project management solutions on an EPCM basis for strategic asset upgrades or renewal programmes.